The construction landscape has dramatically changed over the last couple of years. With projects becoming increasingly complex, sustainable, and technology-driven, the need for seamless collaboration between multidisciplinary teams has never been higher. One of the most critical aspects of ensuring this collaboration is MEP coordination, which brings together in one cohesive, conflict-free model the mechanical, electrical, and plumbing systems.

At Genesis Infoserve, we believe that successful construction outcomes depend not only on structural integrity but also on how efficiently MEP systems integrate within the design and execution process. As digital transformation becomes mainstream, MEP coordination through advanced MEP modelling has become more of a necessity rather than an option.

Understanding the Concept of MEP Coordination

MEP coordination is the detailed integration of the designs of mechanical, electrical, and plumbing systems so that they will function together in harmony within the overall structure. This provides a bridge between the design vision and real-world constructibility.

With intelligent MEP modelling, clashes are identified and resolved before they arrive on site, reducing rework, delays, and unforeseen costs. In today’s construction ecosystem, where timelines are tight and budgets are under scrutiny, this proactive approach saves time, saves money, and improves collaboration among project stakeholders.

Why MEP Coordination has become a Project Essential in 2025

Modern construction companies thrive on precision, sustainability, and smart technology. Here’s why MEP coordination has become indispensable in every construction project today:

1. Design Conflict Elimination Before Construction

In a typical building, the mechanical ducts, electrical conduits, and plumbing pipes often have to share very limited ceiling or wall space. Poor MEP coordination results in clashes of the systems, leading to costly delays once construction gets underway. Advanced coordination ensures that every component is correctly positioned within the 3D model to avoid onsite conflicts before they occur.

2. Simplifying Multidisciplinary Collaboration

Construction projects involve architects, structural engineers, MEP consultants, and contractors. MEP coordination acts as the communication hub, allowing the various teams to visualize and integrate their work in one single BIM environment for better decisions, swifter approval, and more synchronized executions.

3. Minimizing Rework and Cost Overruns

According to recent reports from the industry, reworks arising from design errors can add up to 10% to a project’s total cost. With MEP coordination empowered by BIM-based MEP modelling, teams can catch potential problems before they escalate, paving the way for a more predictable construction phase and cost-efficient delivery.

4. Improving Sustainability and Energy Efficiency

Modern building projects are designed according to green building standards and energy efficiency goals. MEP coordination helps optimize system layouts and routing for better airflow and less material waste, guaranteeing better operational performance. It enables the design teams to provide building systems that, with simulation tools, assist in long-term sustainability targets.

5. Supporting Prefabrication and Modular Construction

Prefabrication and modular construction are on the rise; both are highly dependent on accuracy. Precise MEP modelling ensures that designs ready for fabrication are prepared off-site with few or no errors, hence improving productivity and reducing project delivery times definite competitive advantage in today’s fast-paced construction market.

6. Enhancing Facility Management and Maintenance

Even after the project is completed, MEP coordination adds value. The as-built MEP model serves as a digital reference for facility management, helping maintenance teams understand system layouts, access points, and service connections. This minimizes downtime and leads to smoother building operations.

MEP Modelling: The Digital Foundation of Coordination

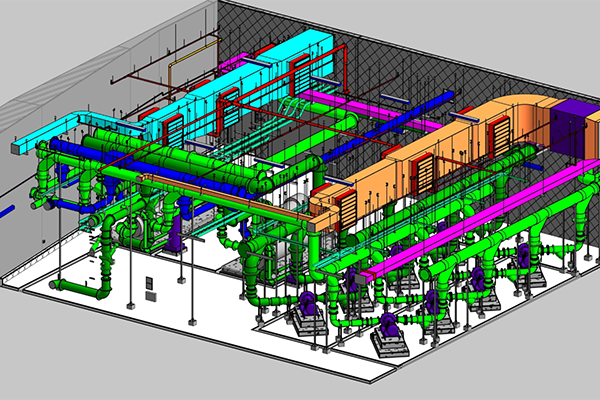

At the heart of effective MEP coordination is MEP modelling: creating intelligent 3D representations of mechanical, electrical, and plumbing systems in a BIM environment.

Unlike traditional 2D drawings, MEP modelling offers a visual, data-rich environment that fosters collaboration and accuracy. It allows the engineer to analyze how HVAC ducts interact with structural beams, check lighting layouts, or assess plumbing routes-all in one shared digital model.

Integration with advanced tools, such as Autodesk Revit, Navisworks, and BIM 360, makes coordination more intuitive. Clash detection, model reviews, and constructability validation by teams are possible in real time.

Emerging Trends in MEP Coordination in 2025

The future of MEP coordination is changing with technology, sustainability, and automation. Here are the major influences that will shape this field in 2025:

1. Coordination of AI and Automation

Artificial Intelligence is now streamlining clash detection and model validation. Thus, automated rule-based checking systems find mistakes more quickly, allowing engineers to spend more time on optimization rather than manual fixes.

2. Digital Twins and Real-Time Monitoring

MEP modelling will evolve into digital twins-intelligent models that deliver real-time performance insight-with the integration of IoT sensors. This enables teams to predict maintenance needs, track energy usage, and optimize building operation throughout the asset lifecycle.

3. Cloud-Based Collaboration

Clouds allow for worldwide team coordination. Now, designers, contractors, and clients access the models anywhere and at any time, which makes the MEP coordination more transparent, agile, and responsive.

4. Sustainability and Integration of Smart Building

The march toward net-zero buildings is driving MEP design to new heights. Coordinated MEP models now integrate renewable energy systems, smart lighting, and advanced HVAC automation for optimized energy efficiency.

How Genesis Infoserve Delivers Excellence in MEP Coordination

At Genesis Infoserve, MEP coordination brings together technological precision with real-world constructability. We work closely with architects, structural engineers, and contractors to ensure that all building systems are fully integrated and clash-free before the first brick is laid.

Our process includes:

Comprehensive MEP modelling:

leading BIM platforms are used to create intelligent 3D models by our team to ensure system compatibility.

Clash Detection & Resolution:

Inter-system conflicts are avoided through multi-level coordination checks.

Constructability Analysis:

Every design will be reviewed for on-site practicality to ensure smoother installation.

Information-rich deliverables:

Our models are enhanced with metadata for materials, specifications, and maintenance details by our models.

Continuous Collaboration:

We believe in real-time communication with all stakeholders through cloud-based tools.

Whether it’s a high-rise residential tower, a hospital, an industrial plant, or a commercial complex, Genesis Infoserve’s MEP coordination services ensure every system functions flawlessly within the design intent, delivering projects that are smarter, safer, and more sustainable.

The Bottom Line

Precision, communication, and foresight are the modern keys to construction success, and MEP coordination brings all three together. It’s an invisible backbone that supports seamless project execution and long-term operational efficiency. As the industry continues to adopt digital transformation and smart technologies, MEP coordination and MEP modelling will be at the core of achieving design accuracy, cost control, and sustainability. At Genesis Infoserve, we don’t just coordinate; we create synergy between systems, disciplines, and teams. Having deep expertise in MEP coordination, we at Genesis Infoserve help our clients build smarter, faster, and more efficiently for today and the future.